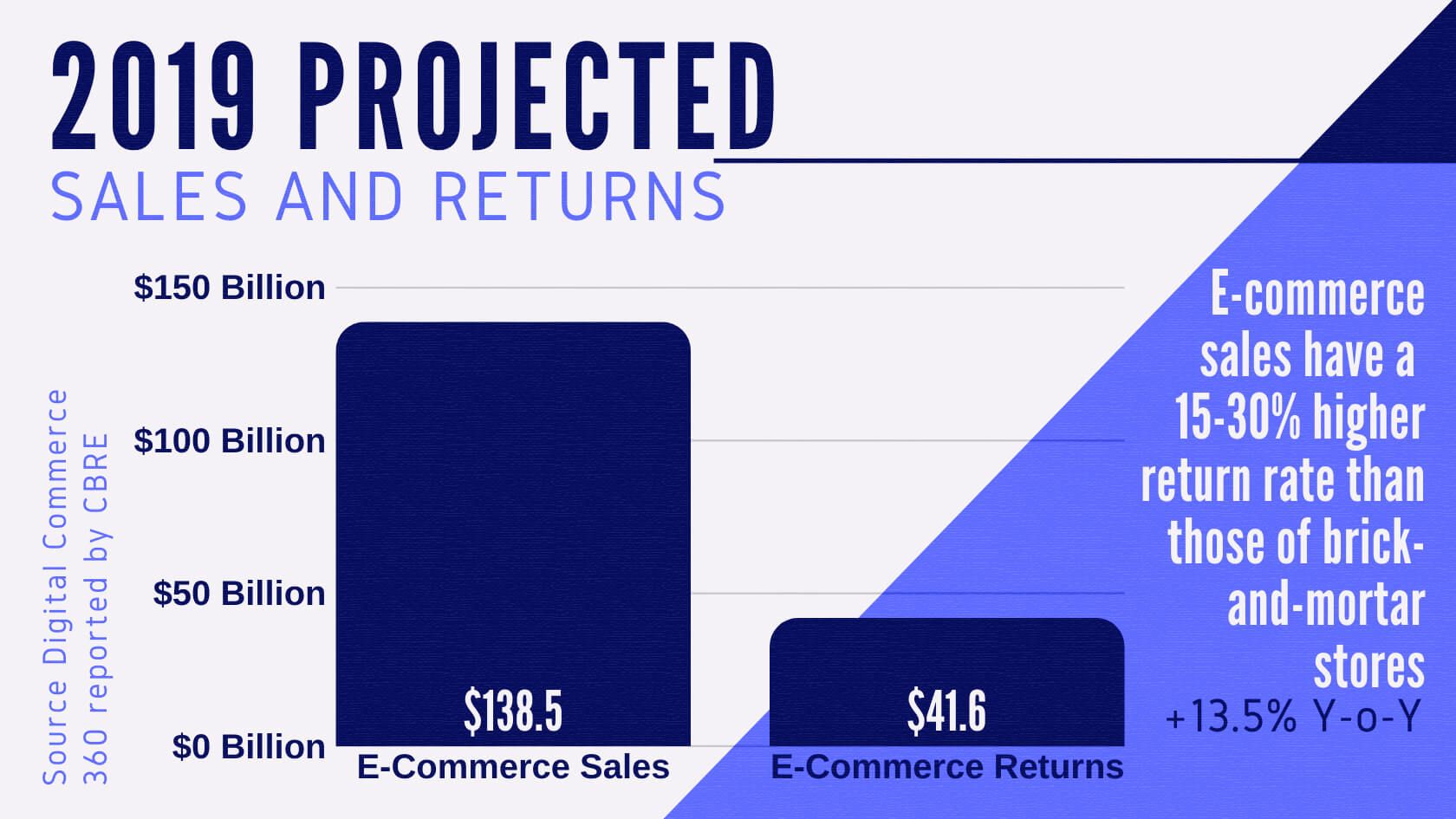

The Importance of Reverse Logistics as 2019 Holiday Returns Could Reach $41.6 Billion

The CBRE, an industrial real estate firm and a global leader in the provision of outsourcing services to major occupiers, released a report detailing figures from the 2019 U.S. holiday e-commerce sales and returns. The CBRE’s recent report states that e-commerce sales are expected to reach $138.5 billion, with the total value of e-commerce returns this holiday season to hit $41.6 billion. This represents a 13.5% annual increase.

The number of e-commerce orders and goods purchased online continues to grow each year, but the returns part of the process is often overlooked by businesses. Returning products without a streamlined process can lead to sizeable financial losses. The report indicates products that depreciate in value quickly, such as apparel, can lose 20% – 50% of its value in 8 to 16 weeks. However, it is possible to prevent such losses.

Products like these make it vital for a company to utilize an efficient reverse logistics process. Reverse logistics can be described as products that are returned and pushed back into the supply chain, a process that most commonly occurs after the December holiday season.

Furthermore, the overall rate of returns is growing by about 10% annually, straining storage space. The reverse logistics process can require 15% – 20% more space than outbound logistics, which, combined with the annual growth rate, can make the process logistically and financially difficult.

Report Details on Reverse Logistics

The report goes into further detail that the rate of returns through the e-commerce channel can fall anywhere between 15% – 30%. This number becomes more significant when combined with the fact that the average rate of returns for merchandise to a physical, brick or mortar location is just 8%.

Retailers often look to external partners to help handle their returns, often turning to logistics and 3PL companies, like R+L Global Logistics. We invest heavily in technology and warehouse management systems that make us better equipped to assist in the reverse logistics process.

The CBRE report detailed that every year the returns process results in about 5 billion pounds of waste and 15 million metric tons of carbon emissions from transportation. As retailers work to include sustainability goals, having a well run reverse logistics operation becomes increasingly important.

The report reads, “returns provide opportunities for product re-use through secondary marketplaces, reducing environmental impact and allowing retailers to recapture a portion of a product’s value.” Therefore, an efficient reverse logistics process is good for the company financially, environmentally, and socially.

Reverse Logistics Challenges

In order to remain competitive, retailers must meet consumer demand for a simple return process. Consumers want as little hassle involved in returning their products as possible, while businesses with online returns need to effectively manage shipping, handling, and related labor costs. These two factors make it essential to have a streamlined reverse logistics process within the business.

The report mentions that the biggest challenges related to reverse logistics include:

- Cost control

- Product depreciation

- Increased shipments and handling

- Increased pressure on an already stressed supply chain

Other factors that can affect shipped returns are processing times, liquidation recovery, and manual processes. These variables resulted in $50 billion in lost profit margin per year and more than $10 billion in needless shipments and merchandise touches in warehouses.

Reverse logistics is a big deal, and it’s only getting bigger. There is a myriad of moving parts involved with the retail supply chain and logistics processes. Retailers, e-commerce business, and logistics service providers should take adequate steps to ensure that the process is done right to solidify smooth operations after the holiday season.

Handling Your Reverse Logistics with R+L Global Logistics

Looking for a logistics provider to assist with your reverse logistics after the holiday season? R+L Global Logistics has the infrastructure and global network to manage your reverse logistics quickly and effectively.

Supply chain management sometimes requires material to move in the reverse direction and we offer a wide array of supply chain solutions to expedite the flow of products while minimizing operational costs. Our team of dedicated supply chain consultants can help with:

- Demand planning and forecasting

- Production scheduling in multiple facilities

- Strategy design to lower your logistics and transportation risk

- Inbound operations

- Outbound operations

- Warehousing

- Order fulfillment

- Customs brokerage

- Delivery of finished goods

We want you to utilize an efficient supply chain, which provides you and your customers with the products you need, when you need them. Call 877-510-9133 to speak with one of our experienced team members today and start the reverse logistics process!