Delays Caused by the Coronavirus May Lead to Moving Manufacturing out of China

Companies have been working to minimize disruptions caused by the coronavirus, but those efforts are becoming more difficult as the situation progresses. Economists and business leaders alike expect the viral outbreak to have an effect on the overall economy in the first quarter.

The Wall Street Journal’s monthly economist survey for February reported that 84% of economists believe the coronavirus will have a small impact on the U.S. gross domestic product. Fortunately, the small impact will be less than 0.5%. However, there is still a level of uncertainty for businesses operating in the region as factories remain closed and the virus continues to spread.

The CEO of Kering (Gucci’s parent company), François-Henri Pinault, stated on February 12 that, “Due to the evolving nature of this situation, it is impossible at this time to fully evaluate its impact on our businesses and how fast they will recover.” Additionally, “we are hearing lots of different theories on the speed and shape of the rebound, but the reality is that it is too early to predict.”

The American Chamber of Commerce (AmCham) in Shanghai conducted a survey of member companies with manufacturing operations in Shanghai, Suzhou, Nanjing, and the wider Yangtze River Delta. The survey took place from February 11-14 and included 109 responding members. Within the survey:

- 48% of companies reported their global operations have already been impacted by the shutdown

- 78% of companies do not have sufficient staff to run a full production line

- 41% of companies say lack of staff is their biggest challenge in the next 2-4 weeks

- 30% of companies say logistics issues will be their biggest concern

- 58% of companies expect demand for their output to be lower than normal

The current coronavirus situation is potentially giving logistics and supply chain managers second thoughts about using Chinese manufacturers in their supply chain. China is a big player in manufacturing, causing managers to seriously weigh the pros and cons of moving manufacturing out of China. Do they continue to wait out the situation and hope the virus clears up soon? Or do they anticipate little positive change and start the moving process?

Standstill in China’s Hubei Province

Hubei Province is home to many of the manufacturing operations that U.S. companies rely on, and unfortunately, it’s also the epicenter of the coronavirus. Chinese officials in Hubei’s provincial government have stated that companies cannot restart operations before today, February 21.

The Wall Street Journal did report that there are some exceptions for companies that produce medical supplies and food, but that still leaves many other industries without their manufacturing operations. An analysis by Dun and Bradstreet stated that 92% of the companies with tier one suppliers in the impacted region are based in the U.S.

Shippers are now seeking alternative suppliers outside of China to try and make up for delays caused by the production standstill in Hubei.

Other Supplier Options

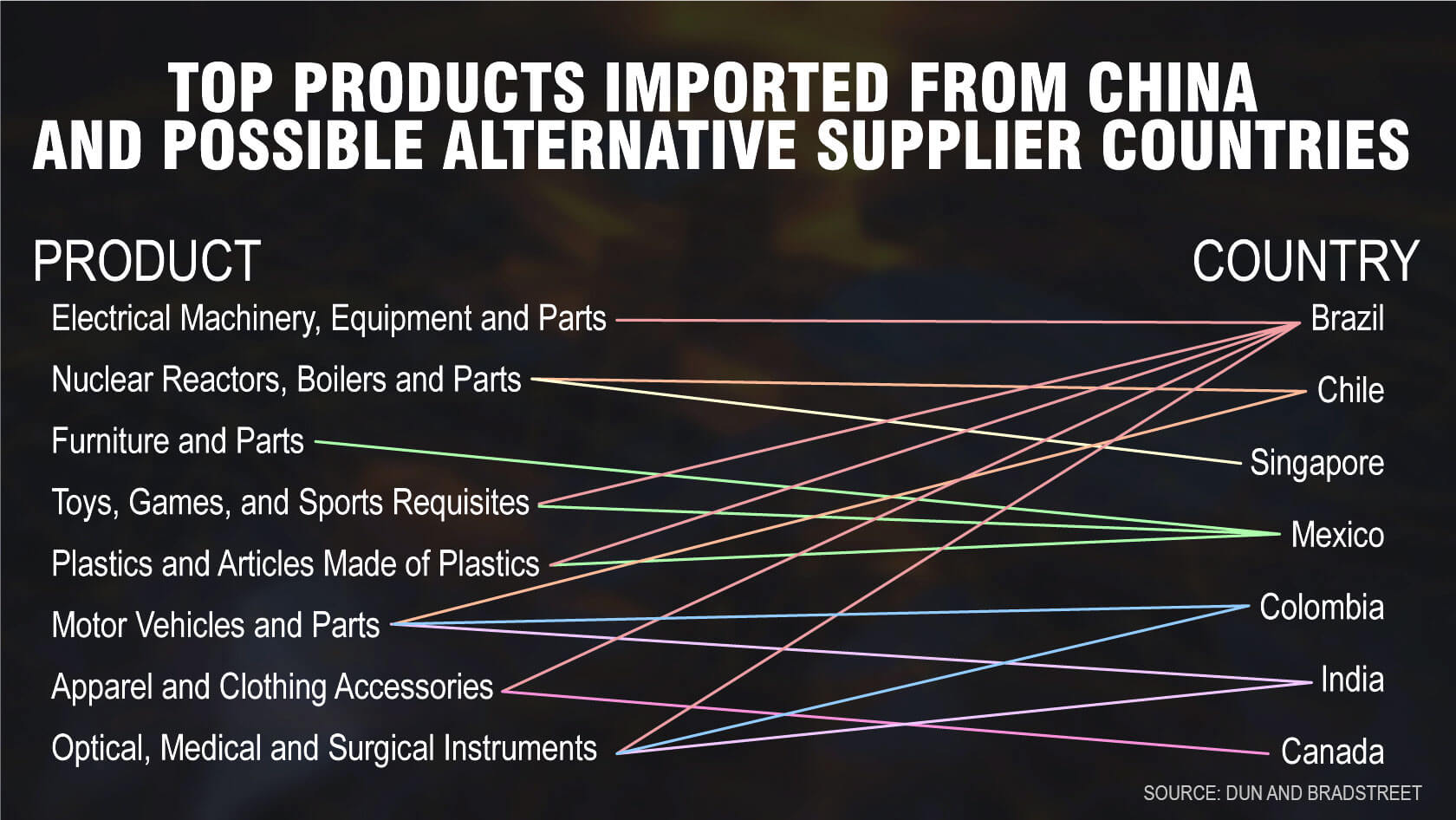

Companies that choose to change supplier sources will base their location change on exactly what product they need. For instance, furniture companies could choose new suppliers in Mexico while electrical machinery could be sourced from Brazil. Dun and Bradstreet broke down some of the supplier alternatives in its report.

However, not all suppliers will change manufacturing operations. Those that choose to wait out the situation will continue to face challenges, even when the virus stops spreading.

Chinese factories will likely experience a backlog of orders when they reopen, so it may be best to wait to place new orders. Rates for ocean shipping between China and the U.S. could increase when production does resume. For now, though, demand is low and carriers continue to face blank sailings.

Future Forecast

While companies and factories are starting to re-open, it’s hard to say when they will return to full capacity. Manufacturing operations are expected to start resuming over the next couple of weeks. Almost 70% of factories will partially resume working today, February 21, and another 22% are expected to be operational before that.

Nonetheless, 30% of companies participating in the AmCham survey said they’ll move operations out of China if they are unable to re-open their factories.

The coronavirus still has the capability to affect the global economy, specifically China and the U.S., the world’s two largest economies. On a positive note, experts do state that both countries could see a rebound of the next few months if the outbreak is contained relatively soon.

Restarting operations takes time as companies reposition equipment and crews, both in the factory and throughout the supply chain process. The virus hasn’t caused any catastrophic changes in manufacturing and operations yet, but the future is unknown.

R+L Global Logistics Can Help Move Your Manufacturing out of China

R+L Global Logistics is well-equipped to help move your manufacturing operations and assist with any other international supply chain needs. We provide a wide variety of international shipping and logistics service, including:

- Air Freight

- Air Charters

- Customs Brokerage

- Import/Export

- Ocean

- Warehousing

Our team of experienced global shipping professionals will work through any delays caused by the coronavirus and communicate with you quickly and effectively to minimize the impact on your operations. Call and speak to one of our team members at 877-510-9133 or chat with one of our experienced customer service representatives today to get started!